Understanding PVDF Coatings: What Makes Them the Smart Roofing Choice

When it comes to selecting the right finish for a metal roof, performance and longevity matter most. PVDF coatings are widely recognized for their exceptional ability to resist fading, weathering, and corrosion, even in the harshest environmental conditions. Understanding PVDF roof coatings is essential for anyone looking to invest in a durable, low-maintenance, and energy-efficient roofing solution that stands the test of time. These coatings offer more than just surface protection, they are engineered to provide consistent performance year after year, reducing the need for frequent maintenance and repairs.

PVDF coatings are not simply another layer of paint; they represent a sophisticated blend of advanced chemistry and precision engineering designed to maximize the lifespan of a metal roof while maintaining its visual appeal. Their unique formulation allows the coatings to withstand extreme temperature fluctuations, resist chemical exposure, and retain vibrant color for decades. Whether applied to commercial, industrial, or coastal projects, PVDF coatings deliver a measurable long-term return on investment, making them a practical and smart choice for builders, contractors, and property owners seeking a reliable roofing solution that combines aesthetics with performance.

What Are PVDF Roof Coatings?

PVDF stands for Polyvinylidene Fluoride, a high-performance fluoropolymer resin known for its exceptional strength and chemical resistance. PVDF coatings are made with a blend that includes at least 70 percent PVDF resin combined with acrylic and other additives. This unique formulation forms a strong, stable bond that protects metal substrates from ultraviolet radiation, oxidation, and environmental damage.

In practical terms, PVDF coatings serve as a shield. They guard against fading, chalking, cracking, and corrosion while enhancing the appearance of the roof. The finish remains vibrant and intact for decades, even under continuous sun exposure or in industrial settings where pollutants can accelerate wear.

Understanding PVDF roof coatings begins with recognizing that these finishes are engineered for endurance. Many manufacturers offer fade warranties of up to 30 or even 40 years, proving how reliable and trusted this technology has become across the roofing industry.

Why PVDF Is Considered the Gold Standard

The phrase “gold standard” is often used to describe PVDF coatings for good reason. These coatings outperform other finishes like polyester or silicone-modified polyester (SMP) in nearly every category that matters to builders and architects. From color retention to resistance against extreme weather, PVDF has become synonymous with high-performance roofing protection.

Key Advantages Include:

- Superior Color Retention: The strong carbon-fluorine bonds within the resin prevent UV rays from breaking down pigments, helping roofs maintain their original color for decades.

- Long-Term Durability: PVDF coatings resist peeling, flaking, and cracking even through cycles of extreme heat and cold.

- Resistance to Chemicals and Pollutants: They withstand exposure to acid rain, smog, and industrial contaminants, making them suitable for urban and manufacturing environments.

- Chalking Prevention: Roofs coated with PVDF remain clean and bright, avoiding the powdery residue that can dull lesser finishes.

Performance in Harsh Environments

Understanding PVDF roof coatings also means appreciating how they perform under pressure. These coatings were designed to endure real-world challenges that compromise other finishes.

In coastal climates, salt-heavy air can accelerate corrosion. PVDF’s molecular structure prevents this by creating a stable, non-reactive surface that resists deterioration. In industrial zones, where pollutants and airborne chemicals are constant concerns, PVDF coatings protect against acidic or alkaline exposure that might otherwise eat away at the roof’s surface.

Even in areas prone to snow, ice, or dramatic temperature swings, PVDF coatings maintain flexibility and adhesion. This resilience minimizes the risk of cracking or peeling, which are common issues with standard coatings. As a result, roofs finished with PVDF consistently outperform alternatives, lasting decades longer with fewer signs of wear.

Energy Efficiency and Cool Roof Performance

One of the lesser-known but highly valuable benefits of PVDF coatings is their contribution to energy efficiency. Many PVDF finishes include solar-reflective pigments that help reflect sunlight rather than absorb it. This reduces heat buildup on the roof surface, leading to lower cooling costs and improved comfort inside the building.

This effect is measured by the Solar Reflectance Index (SRI). Roofs with higher SRI values stay cooler under direct sunlight, reducing the load on HVAC systems and promoting overall energy efficiency. For commercial buildings, this can mean significant cost savings over time. For residential or mixed-use spaces, it can enhance comfort and sustainability.

Understanding PVDF roof coatings includes recognizing how these reflective properties align with modern green building standards. By minimizing heat absorption and extending roof life, PVDF contributes to a more sustainable building and long-term operational efficiency.

Aesthetic and Design Flexibility

While performance is critical, appearance also plays a major role in roofing decisions. PVDF coatings are valued for their design versatility and visual appeal. They are available in a wide range of solid colors, metallic tones, and specialty finishes that mimic natural materials like wood, copper, or weathered steel. This allows architects and designers to achieve specific looks without compromising durability.

The smooth, even finish of PVDF coatings enhances curb appeal and adds value to any structure. Buildings retain a fresh, modern appearance that does not fade with time. For high-end commercial projects, industrial facilities, or residential developments, this aesthetic flexibility helps align design vision with long-term performance goals.

The ability to customize colors and finishes also makes PVDF coatings ideal for matching branding elements or architectural themes. From sleek modern coil or sheets to textured surfaces that capture light differently, the visual potential of PVDF is nearly limitless.

Longevity and Return on Investment

A roof is one of the most important investments in any building project. It protects everything beneath it and influences overall property value. PVDF coatings help ensure that this investment lasts as long as possible while reducing ongoing costs.

Because PVDF finishes resist fading, corrosion, and surface degradation, they extend the lifespan of the roof material itself. This minimizes the need for repainting or early replacement. Over a 20 to 40-year period, the long-term savings can be significant, especially when factoring in reduced maintenance and energy costs.

Understanding PVDF roof coatings means recognizing that their value is not just about aesthetics or chemistry, it is about lifecycle cost efficiency. Property owners, builders, and facility managers who choose PVDF-coated metal roofs benefit from fewer repairs, consistent performance, and enhanced resale potential.

PVDF vs. Other Roof Coatings

There are several types of coatings available for metal roofs, but few come close to matching the performance of PVDF. Polyester and SMP coatings are more affordable initially, but they tend to degrade faster under UV exposure and may fade within just a few years. PVDF, on the other hand, retains its color, gloss, and protective properties for decades.

While PVDF coatings may have a higher upfront cost, the long-term return on investment makes them more economical. Fewer maintenance requirements and extended lifespan offset the initial expense. For projects where durability, color retention, and long-term value are priorities, PVDF is the superior choice.

Applications Across Industries

PVDF coatings are used in a variety of industries due to their adaptability and reliability. They are ideal for:

- Commercial buildings that require a long-lasting, low-maintenance exterior finish.

- Industrial facilities where chemical resistance and structural integrity are essential.

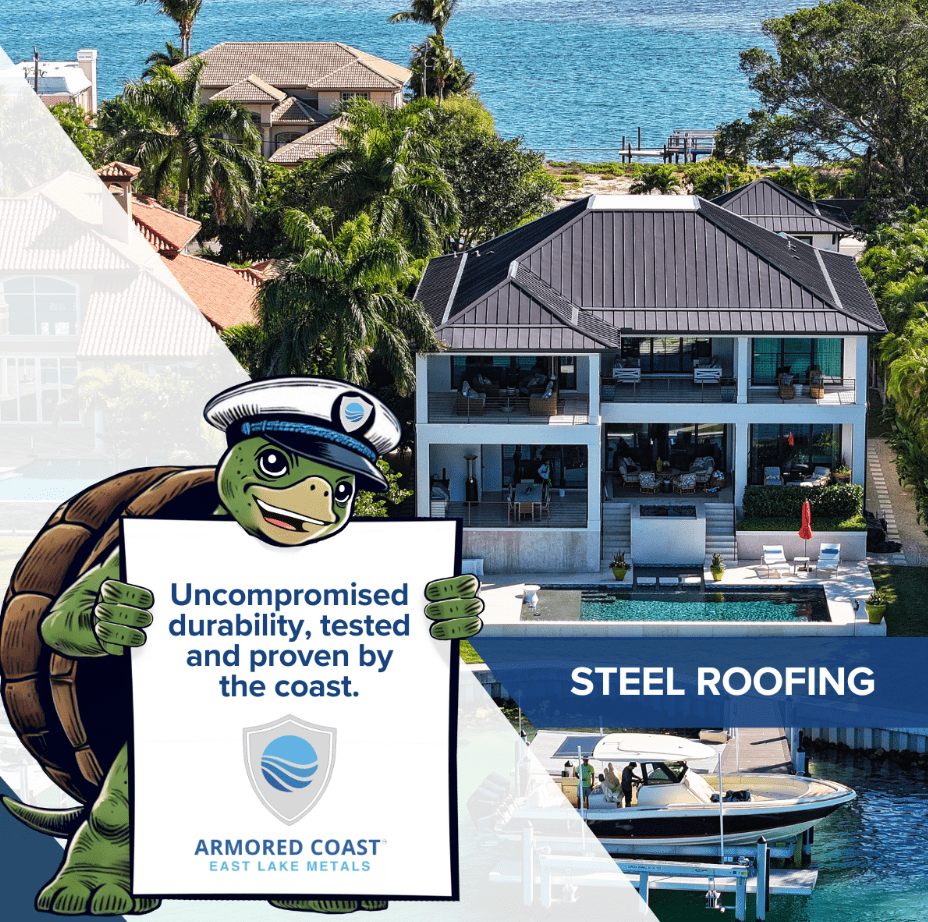

- Coastal developments where salt exposure can quickly degrade standard coatings.

- Architectural projects that demand both aesthetic appeal and high performance.

Why Understanding PVDF Roof Coatings Matters

Understanding PVDF roof coatings allows property owners, architects, and builders to make informed decisions about one of the most critical elements of construction. The roof is a long-term investment, and the coating that protects it determines how well it performs over time. PVDF technology represents the best combination of science, sustainability, and design flexibility available today.

As environmental regulations tighten and the demand for energy-efficient, sustainable materials grows, PVDF coatings stand out as a proven, future-ready option. Their ability to deliver both durability and visual appeal ensures that buildings remain protected and attractive for decades.

Partnering with East Lake Metals

East Lake Metals understands the importance of performance, reliability, and appearance when it comes to metal roofing. That is why we work with materials and coatings that meet the highest standards in the industry, including PVDF. Our team is here to help builders, architects, and property owners choose finishes that deliver maximum value and long-term protection.

Ready to learn more about the benefits and applications of PVDF coatings? Contact East Lake Metals today to discuss your next project and discover how PVDF-coated metal products can help you achieve lasting performance and visual impact.